A manual transaxle diagram is a visual guide illustrating the components and their interactions within a manual transmission system, aiding in understanding its operation and troubleshooting․

1․1 Overview of Manual Transaxle

A manual transaxle is a component in vehicles that combines a manual transmission and a differential into one unit, enabling power transfer from the engine to the wheels․ It consists of gears, shafts, synchronizers, and axle parts, all working together to facilitate smooth gear shifting and torque distribution․ The transaxle is essential for optimizing power flow and ensuring efficient vehicle operation under various driving conditions․ By understanding its structure, drivers and mechanics can better diagnose issues and perform maintenance․ The manual transaxle is widely used in front-wheel-drive vehicles, providing a compact and effective solution for power transmission․ Its design allows for precise control over speed and torque, making it a critical system for vehicle performance and reliability․

1․2 Importance of Understanding Manual Transaxle Diagrams

Understanding manual transaxle diagrams is crucial for diagnosing and resolving issues efficiently․ These diagrams provide a clear visual representation of the components, such as gears, shafts, and synchronizers, and how they interact․ By studying the layout, individuals can better comprehend the flow of power from the engine to the wheels․ This knowledge is essential for mechanics and drivers alike, as it enables precise troubleshooting and maintenance․ It also helps in identifying worn or damaged parts, ensuring timely repairs and preventing further damage․ Moreover, understanding the diagram enhances the ability to perform routine maintenance, such as lubrication and clutch replacement, which are vital for smooth operation․ For drivers, this insight improves gear-shifting techniques, reducing wear and tear on the system․ In summary, a manual transaxle diagram is an invaluable tool for optimizing performance, reliability, and longevity of the vehicle’s transmission system․

Components of a Manual Transaxle

A manual transaxle comprises essential components like gears, shafts, synchronizers, differential, axle parts, clutch, and flywheel, all working together to transfer power from the engine to the wheels efficiently․

2․1 Gears and Shafts

Gears and shafts are fundamental components of a manual transaxle, enabling speed and torque adjustments․ The gears are mounted on shafts, which rotate to transmit power․ They are designed to engage in different combinations, allowing the driver to shift through various gear ratios․ Synchronizers facilitate smooth engagement between gears and shafts, ensuring synchronized motion․ The input shaft connects to the clutch, while the output shaft transfers power to the differential․ Together, gears and shafts play a critical role in optimizing power delivery, ensuring efficient vehicle operation across diverse driving conditions․ Understanding their interaction is essential for diagnosing issues and maintaining optimal performance․

2․2 Synchronizers and Their Function

Synchronizers are critical components in a manual transaxle, ensuring smooth and precise gear engagement․ Their primary function is to synchronize the speed of the gear and shaft before engagement, preventing grinding or clashing during shifts․ By using frictional force, synchronizers align the rotation of the collar and gear, allowing seamless transitions․ This mechanism is essential for maintaining driver control and reducing wear on transmission components․ Synchronizers also contribute to efficient power transfer by minimizing mechanical stress during gear changes․ Proper functioning of synchronizers is vital for smooth operation, as faulty synchronizers can lead to hard shifting or gear slippage․ Understanding their role helps in diagnosing and addressing common transmission issues, ensuring optimal performance and longevity of the manual transaxle system․

2․3 Differential and Axle Parts

The differential and axle parts are essential components of a manual transaxle, responsible for transferring power from the gearbox to the wheels․ The differential allows the wheels to rotate at different speeds, particularly during turns, ensuring smooth and efficient power delivery․ Axle parts, including constant velocity (CV) joints, connect the differential to the wheels, enabling flexible movement while maintaining power transmission․ These components work in harmony to adapt to varying driving conditions, such as cornering or uneven terrain․ Proper functioning of the differential and axle system is critical for maintaining traction, stability, and overall vehicle control․ Understanding their operation is key to diagnosing issues like uneven tire wear or vibration, ensuring optimal performance and longevity of the manual transaxle․

2․4 Clutch and Flywheel

The clutch and flywheel are critical components in a manual transaxle system, enabling the driver to disengage and engage power from the engine to the gearbox smoothly․ The clutch is a friction plate that connects to the flywheel, mounted on the engine’s crankshaft․ When the driver presses the clutch pedal, it disengages the engine from the transmission, allowing gear shifts without grinding․ Over time, the clutch can wear out due to frequent use, leading to issues like slippage or difficulty shifting gears․ A worn clutch may also produce a burning smell․ Regular inspection and timely replacement of the clutch and flywheel are essential to maintain smooth operation and prevent further damage to the transaxle․ Proper alignment and adjustment of these components are crucial for optimal performance and longevity of the manual transmission system․

How a Manual Transaxle Works

A manual transaxle transfers power from the engine through gears and shafts, with the clutch engaging or disengaging power flow․ Drivers manually shift gears to optimize speed and torque, ensuring efficient power delivery to the wheels based on driving conditions․

3․1 Power Flow and Gear Ratios

Power flow in a manual transaxle begins with the engine, transferring torque through the clutch to the input shaft․ Gears on the shafts engage to adjust speed and torque, allowing the driver to optimize power delivery․ Gear ratios play a crucial role in determining vehicle speed and engine RPM, enabling efficient performance across various driving conditions․ Lower gears provide more torque for acceleration, while higher gears optimize speed at lower RPM․ The manual transaxle ensures smooth power transition by engaging and disengaging gears through the clutch, allowing drivers to control the vehicle’s performance effectively․ Understanding gear ratios is essential for maximizing fuel efficiency and driving comfort, as they directly influence how power is distributed to the wheels․

3․2 Torque Distribution and Speed Adjustment

Torque distribution in a manual transaxle is managed by the differential, ensuring power is split between the drive wheels․ This system allows wheels to rotate at different speeds during cornering, enhancing traction and stability․ Speed adjustment is achieved through manual gear shifts, enabling drivers to match engine RPM with road conditions․ Lower gears deliver higher torque for uphill climbs or heavy loads, while higher gears optimize speed on flat roads․ The synchronizers facilitate smooth gear transitions by aligning shaft speeds, preventing abrupt shifts․ Together, torque distribution and speed adjustment ensure efficient power delivery, providing drivers with precise control over the vehicle’s performance and handling․ This mechanical harmony is essential for both performance and safety on the road․

3․3 Role of the Clutch in Power Engagement

The clutch plays a crucial role in power engagement within a manual transaxle by enabling the disengagement and re-engagement of engine power from the transmission․ When the driver presses the clutch pedal, it separates the engine from the transaxle, allowing gears to shift without grinding․ This temporary disconnection prevents damage to the transmission during gear changes․ Once the pedal is released, the clutch reconnects the engine’s power, ensuring smooth torque transfer to the wheels․ The clutch’s operation is essential for seamless gear transitions, enabling drivers to shift gears efficiently․ Proper control of the clutch pedal is vital to avoid wear and tear on the clutch and related components, ensuring optimal performance and longevity of the manual transaxle system․

Manual Transaxle Diagram Explained

A manual transaxle diagram is a detailed visual guide that illustrates the internal components and their relationships, helping to understand the mechanism and troubleshoot issues effectively․

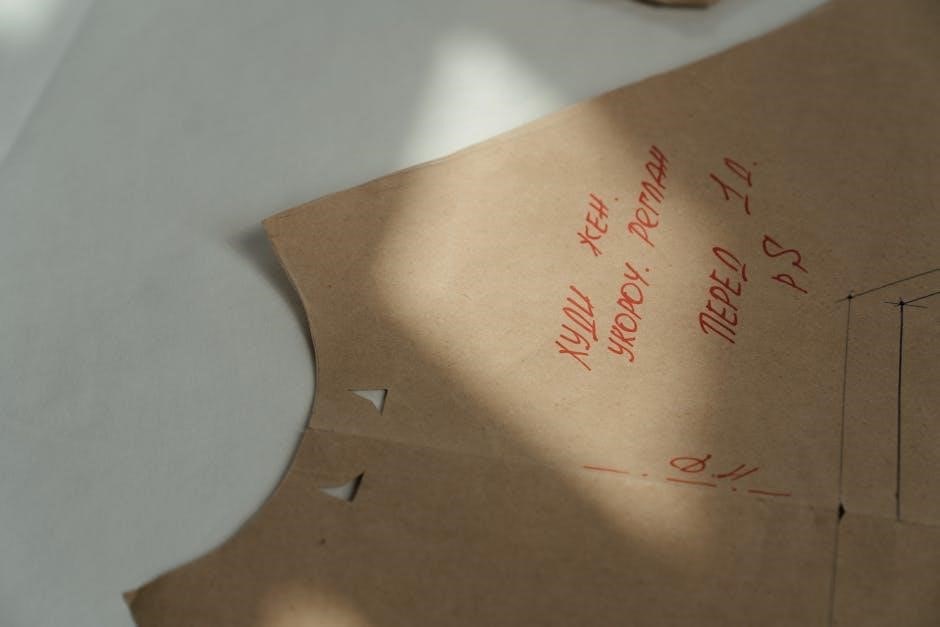

4․1 Visual Representation of Components

A manual transaxle diagram provides a clear and detailed visual representation of all the internal components, such as gears, shafts, synchronizers, and the differential․ These components are illustrated in their precise locations, showing how they connect and interact within the gearbox and axle system․ The diagram highlights the clutch assembly, flywheel, and input shaft, which play a critical role in power transfer․ It also depicts the layout of the gear teeth, bearings, and seals, offering a comprehensive view of the mechanical structure․ This visual guide is essential for understanding how power flows through the system and how each part contributes to smooth operation․ By examining the diagram, mechanics and drivers can identify potential issues, such as worn gears or misaligned shafts, and perform necessary repairs․ The visual clarity of the diagram makes it an invaluable tool for both diagnostics and maintenance․

4․2 Interaction Between Gears and Synchronizers

The manual transaxle diagram illustrates the intricate interaction between gears and synchronizers, which is crucial for smooth gear shifting․ Synchronizers are responsible for aligning the speed of the input shaft with the desired gear before engagement, ensuring a seamless transition․ When the driver presses the clutch and moves the gearshift, the synchronizer collar engages with the gear, locking it into place․ The gears, mounted on shafts, rotate at specific speeds based on the selected gear ratio․ The diagram shows how the synchronizers facilitate this process by adjusting the shaft speed, preventing gear clashing and ensuring smooth power delivery․ This interaction is vital for maintaining control and efficiency during acceleration and deceleration․ Understanding this mechanism through the diagram helps in diagnosing issues like hard shifting or gear slippage, which often stem from synchronizer wear or misalignment․

4․3 Layout of the Gearbox and Axle System

The manual transaxle diagram provides a detailed visual representation of the gearbox and axle system layout, showcasing how these components are integrated to facilitate power transfer․ The gearbox contains gears, shafts, and synchronizers arranged in a specific configuration to enable smooth gear transitions․ The axle system, including the differential and CV joints, is connected to the gearbox, ensuring power is delivered to the wheels efficiently․ The diagram highlights how these parts are interconnected, allowing drivers to understand the flow of power from the engine through the gearbox and to the wheels․ This layout is crucial for optimizing power delivery and torque distribution, especially in front-wheel-drive vehicles where the transaxle combines the transmission and differential into a single unit․ The visual arrangement helps in diagnosing issues and appreciating the engineering behind the system․

Common Issues and Troubleshooting

Common issues with manual transaxles include hard shifting, gear slippage, and clutch wear․ Troubleshooting often involves inspecting the synchronizers, gear engagement, and fluid levels․ A diagram helps identify faulty components and guides repairs, ensuring smooth operation and preventing further damage․

5․1 Hard Shifting and Synchronizer Problems

Hard shifting in a manual transaxle often stems from worn or damaged synchronizers, which are critical for smooth gear engagement․ When synchronizers fail, gears may not align properly, leading to difficulty in shifting and potential grinding noises․ This issue can also arise from improper clutch engagement or insufficient transmission fluid levels, which lubricate and cool the components․ Over time, high mileage or aggressive driving habits can exacerbate synchronizer wear․ Symptoms include a stiff gearshift, resistance when shifting, or a “grinding” sensation during gear changes․ If left unaddressed, hard shifting can lead to further damage, such as gear tooth wear or complete synchronizer failure․ Troubleshooting involves inspecting the synchronizers, checking lubrication levels, and replacing worn components to restore smooth operation․ Regular maintenance, such as fluid changes, can help prevent these issues and extend the lifespan of the transaxle․

5․2 Gear Slippage and Its Causes

Gear slippage in a manual transaxle occurs when gears fail to maintain proper engagement, causing unintended shifts or lack of power transfer․ This issue often results from worn or damaged gear teeth, which can no longer hold their position․ Additionally, excessive wear on synchronizers or clutch components can contribute to slippage․ Other factors include insufficient lubrication, where gears lack the necessary friction to stay engaged, or misaligned gear components due to improper installation․ Symptoms may include a “slipping” feeling while accelerating, unusual noises during gear changes, or a decrease in vehicle performance․ Addressing gear slippage requires identifying the root cause, whether it be worn parts, lubrication issues, or alignment problems․ Replacing damaged gears, synchronizers, or the clutch, along with ensuring proper lubrication, can resolve the issue and restore efficient power transmission․ Regular inspection and maintenance are key to preventing such problems․

5․3 Diagnostic Steps for Faulty Transaxle

Diagnosing a faulty manual transaxle involves a systematic approach to identify the root cause of the issue․ Begin with a visual inspection of the transaxle for signs of leaks, wear, or damage․ Check the gear oil level and condition, as low or degraded fluid can lead to malfunction․ Listen for unusual noises during operation, such as grinding or clunking sounds, which may indicate worn gears or bearings․ Test for slippage by accelerating through gears; if gears slip or hesitate, it could point to worn synchronizers or clutch issues․ Use diagnostic tools like scan tools or pressure testers to measure internal pressure and detect irregularities․ If symptoms persist, disassemble the transaxle for a closer examination of gears, shafts, and bearings․ Always refer to a repair manual for specific instructions and ensure the workspace is clean to prevent contamination․ Early detection and repair can prevent further damage and extend the transaxle’s lifespan․

Maintenance and Repair

Regular lubrication of gears and shafts ensures smooth operation, while replacing worn clutches and seals prevents slippage and leakage, maintaining optimal transaxle performance and longevity․

6․1 Lubrication of Gears and Shafts

Lubrication is essential for maintaining the performance and longevity of a manual transaxle․ Gears and shafts require consistent lubrication to reduce friction, prevent wear, and maintain smooth operation․ High-quality transmission fluid or gear oil is typically used, as it is designed to withstand the mechanical stresses within the transaxle․ Proper lubrication ensures that moving parts remain cool and function efficiently․ Regular checks and timely replacement of lubricants are crucial, as inadequate lubrication can lead to premature wear, increased noise, and potentially catastrophic damage․ Additionally, lubrication helps prevent corrosion and extends the lifespan of the transaxle components․ By adhering to the recommended lubrication schedule, drivers can ensure their manual transaxle operates smoothly and reliably under various driving conditions․

6․2 Replacing Worn Clutch and Seals

Replacing a worn clutch and seals is crucial for maintaining the performance and integrity of a manual transaxle․ Over time, the clutch can wear out, leading to issues such as slippage, difficulty shifting gears, and a burning smell․ When these symptoms arise, prompt replacement is necessary to prevent further damage to the transaxle․ The process typically involves removing the transmission, inspecting the clutch and flywheel, and installing new components․ Seals should also be replaced if they show signs of leakage to prevent fluid loss and contamination․ Proper alignment and torque specifications must be followed during reinstallation to ensure smooth engagement and disengagement of the clutch․ Regular inspection and timely replacement of these components are key to maintaining the overall health and functionality of the manual transaxle system․

6․3 Preventive Measures for Smooth Operation

Preventive measures are essential to ensure the smooth operation of a manual transaxle․ Regular inspection of the clutch and seals can help identify wear early, preventing costly repairs․ Checking the transaxle for any signs of leakage or damage is also crucial to maintain fluid levels and prevent contamination․ Proper alignment during installation and avoiding aggressive driving habits can reduce stress on the components․ Additionally, ensuring the surrounding systems, such as the gearbox and axle, are well-maintained helps prevent indirect damage to the transaxle․ By adhering to a routine maintenance schedule and addressing issues promptly, drivers can extend the lifespan of the manual transaxle and maintain optimal performance․

Manual Transaxle vs․ Automatic Transmission

A manual transaxle offers greater driver control and mechanical efficiency, while an automatic transmission provides convenience and ease of use, each catering to different driving preferences and needs․

7․1 Key Differences in Mechanism

The manual transaxle relies on a clutch and gearshift, requiring driver input to change gears, whereas automatic transmissions use a torque converter and hydraulic controls for seamless gear shifts․ In manual systems, the clutch disengages the engine from the transmission, allowing manual gear selection through the gearshift․ This process involves synchronizers to align gear speeds, ensuring smooth transitions․ Automatic transmissions, however, rely on pressurized fluid to engage and disengage clutches and bands, automatically shifting gears based on vehicle speed and throttle input․ This fundamental difference in operation leads to distinct driving experiences, with manuals offering more control and automatics providing convenience․ Each mechanism has its own maintenance requirements, with manuals typically needing clutch replacements and automatics requiring fluid changes and filter inspections․

7․2 Efficiency and Driver Control Comparison

Manual transaxles generally offer better fuel efficiency compared to automatic transmissions, especially in skilled hands, due to the direct control over gear shifts․ Drivers can optimize engine RPMs for varying driving conditions, reducing unnecessary fuel consumption․ In contrast, automatic transmissions rely on torque converters and hydraulic systems, which can lead to slightly higher fuel usage, though modern automatics have narrowed this gap․ Manual systems provide greater driver engagement and control, allowing for precise acceleration and deceleration․ Automatics, while more convenient, sacrifice some driver involvement but offer smoother operation in heavy traffic․ The choice often comes down to personal preference, with manuals appealing to enthusiasts and automatics to those prioritizing ease of use․ Both systems have evolved to enhance performance, but their core differences remain in efficiency and driver interaction․

The Role of the Clutch in Manual Transaxle

The clutch engages and disengages power transfer from the engine to the transaxle, enabling smooth gear shifts without grinding, and is essential for precise driver control of the vehicle;

8․1 Function of the Clutch in Power Transfer

The clutch is a critical component in a manual transaxle system, enabling the temporary disconnection of engine power from the transmission․ This allows for smooth gear changes without causing damage to the gears․ When the driver presses the clutch pedal, the clutch disengages the engine from the transaxle, interrupting power flow․ This momentary disconnection is essential for shifting gears seamlessly, as it prevents grinding or wear on the gears․ Once the desired gear is selected and the pedal is released, the clutch re-engages, restoring power transfer․ The clutch’s friction plate facilitates this engagement, ensuring smooth acceleration and deceleration․ Proper clutch operation is vital for maintaining control over the vehicle’s power delivery, making it indispensable in manual transmissions․ Regular maintenance of the clutch is necessary to prevent slippage or failure, which can disrupt power transfer and lead to costly repairs․

8․2 Signs of Clutch Wear and Replacement

Identifying signs of clutch wear is crucial for maintaining smooth operation of a manual transaxle․ Common indicators include a slipping clutch, where the engine RPM increases without a corresponding increase in vehicle speed․ Another sign is difficulty shifting gears, often accompanied by a grinding noise․ A burning smell may also be present due to excessive friction․ If the clutch pedal feels spongy or requires more effort than usual, it may indicate worn-out components․ Additionally, a clutch that engages too high or too low on the pedal stroke can signal wear․ Ignoring these signs can lead to complete clutch failure, requiring costly repairs․ Regular inspection of the clutch and flywheel is recommended to ensure optimal performance․ Replacing a worn clutch promptly prevents further damage to the transaxle and ensures reliable power transfer, maintaining the vehicle’s overall efficiency and drivability․

Understanding and maintaining the manual transaxle is crucial for efficient vehicle operation․ Regular maintenance ensures smooth performance and prevents costly repairs, highlighting the importance of a well-maintained system․

9․1 Key Takeaways from the Manual Transaxle Diagram

A manual transaxle diagram provides a clear understanding of the system’s components and their interactions․ It highlights the role of gears, shafts, and synchronizers in enabling smooth gear transitions․ The diagram also emphasizes the importance of the clutch in disengaging and engaging power flow․ By studying the layout, one can identify potential issues like worn-out parts or fluid leaks․ It serves as a valuable tool for diagnosing problems, such as hard shifting or gear slippage, and guides maintenance tasks like lubrication and seal replacement․ Understanding the diagram helps in troubleshooting and ensures efficient operation, making it essential for drivers and mechanics alike․ Regular inspection and maintenance, as illustrated by the diagram, are crucial for extending the lifespan of the transaxle and preventing costly repairs․

9․2 Importance of Regular Maintenance

Regular maintenance is crucial for ensuring the longevity and efficiency of a manual transaxle system․ Proper lubrication of gears and shafts prevents wear and tear, while checking for fluid leaks helps maintain optimal performance․ Replacing worn components, such as the clutch and seals, addresses issues before they escalate․ Cleaning and inspecting synchronizers and gear teeth can prevent hard shifting and misalignment․ Routine checks on the differential and axle parts ensure smooth torque distribution․ By adhering to a maintenance schedule, drivers can avoid costly repairs and extend the lifespan of the transaxle․ Regular maintenance also enhances driver control and ensures reliable power transfer, making it essential for both performance and safety․ Consistent upkeep guarantees the system operates efficiently, minimizing the risk of unexpected failures during operation․